(click thru to witness an amazing video)

Here’s an excerpt from the accompanying article:

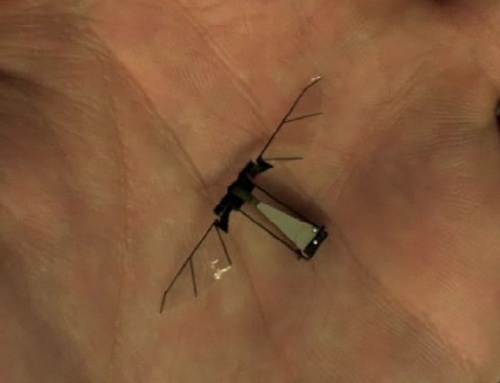

Designing an automated fly implied having the ability to make

lightweight, miniature working parts, a process that Wood says took up

the bulk of his doctoral study, because of the lack of any previous

research on which to draw. “For years, the thrust of our work was ‘How

do we do this?’” says Wood. “There was no existing fabrication

paradigm, given the scale we were operating on, the speed we wanted to

operate with, and things like cost, turnaround, and robustness.” His

research group developed and fabricated a laser carving system that

could meticulously cut, shape, and bend sheets of carbon fiber and

polymer—both strong but lightweight materials—into the necessary

microparts.And how to power those wings to beat 120 times

per second? To keep this 60-milligram robot (the weight of a few grains

of rice) with a 3-centimeter wingspan to a minimal size and weight,

Wood says, you can’t simply use a shrunken version of the heavy DC

(direct current) motors used in most robots. So he and his team settled

on a simple actuator: in this case, a layered composite that bends when

electricity is applied, thereby powering a micro-scale gearbox hooked

up to the wings. Wood says the actuator works even better than its

biological inspiration. The power density—a measure of power output as

a function of mass—of a fly’s wing muscles is around 80 watts per

kilogram; Wood’s wing design produces more than 400 watts per kilogram.

That’s some kick-ass engineering at work. Professor Wood, you are one gnarly dude.

Many thanks to the folks at Telstar Logistics, a key member of the metacool horizontal keiretsu, for bringing this innovation to the attention of our R&D group.

Wow, that is pretty insane! And very cool.